The Brief - The Solution - Additional Images

Brief

During my third year of university, whilst on my work placement, I was trusted to own a full project, from writing a design brief through to production.

The client came to us with a metal enclosure used to help clean commercial pipe systems. Because the whole unit was fabricated by hand out of sheet metal, it was extremely expensive (from memory around £100). They asked that we try to redesign the unit for injection moulding in order to make the product more cost effective.

They wanted the new design to be as similar as possible to their current design internally, due to the various pumps and electronics that had to fit inside. The outside of the unit they wanted to remain the same if possible, but accepting some changes might be required to make it suitable for manufacture and also to account for any new features that might be added.

The Solution

The design went through a lot of iteration, and I made sure keep the client up to date weekly on the progress and in order to make sure they were happy with the direction that the design was taking.

After researching the company, I was really keen on trying to maintain the aesthetic of the unit and the functionality of how the engineers using it would interact with it, in order to make the process of switching to the new design more seamless for them.

Aside from designing the unit with appropriate draft for tooling and sliders, the biggest change that I made was to the handle. In the original design (see photos below), there were two thin sheet metal handles, which were insanely uncomfortable and awkward to use.

In order to keep the envelope size of the unit similar, I designed a retracting handle that would fold flat and then slide into the unit. To use the handle, you would simply pull it out of the back of the unit which would allow you to pivot it upright.

The goal of making the unit more cost effective was met by the design, reducing the unit cost (excluding additional components) from around £100 to approximately £30-£40 (from memory).

Lessons Learnt

Being responsible for every part and assembly within this product gave me the chance to learn so much about design, and more specifically, design for injection moulding. I feel as though, after plenty of feedback from my colleagues and tooling specialists, I grew as a designer during the project.

There were a number parts where I felt I came up with smart design solutions to make manufacture and assembly easier, by combining what were previously separate components and modifying them to allow for easy manufacture.

There were also lessons learnt in regards to how materials move and work after forming - some parts warped after production, making assembly difficult. But I was able to help overcome these issues by providing solutions such as cooling jigs, making modifications to the design to improve stiffness in certain directions and asking the factory to adjust their processes to better suit the requirements of the product.

Overall, this is a product that I am really proud of, being my first ever concept to production design.

Additional Images

Original metal enclosure and cover

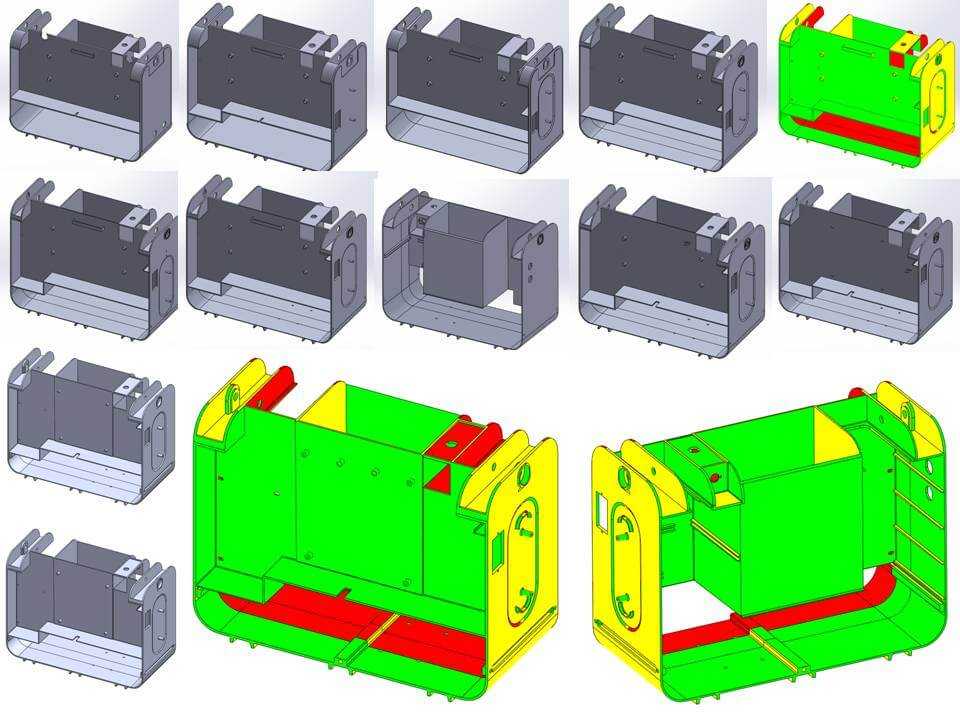

Design progression of the body of the new plastic product including examples of draft analysis

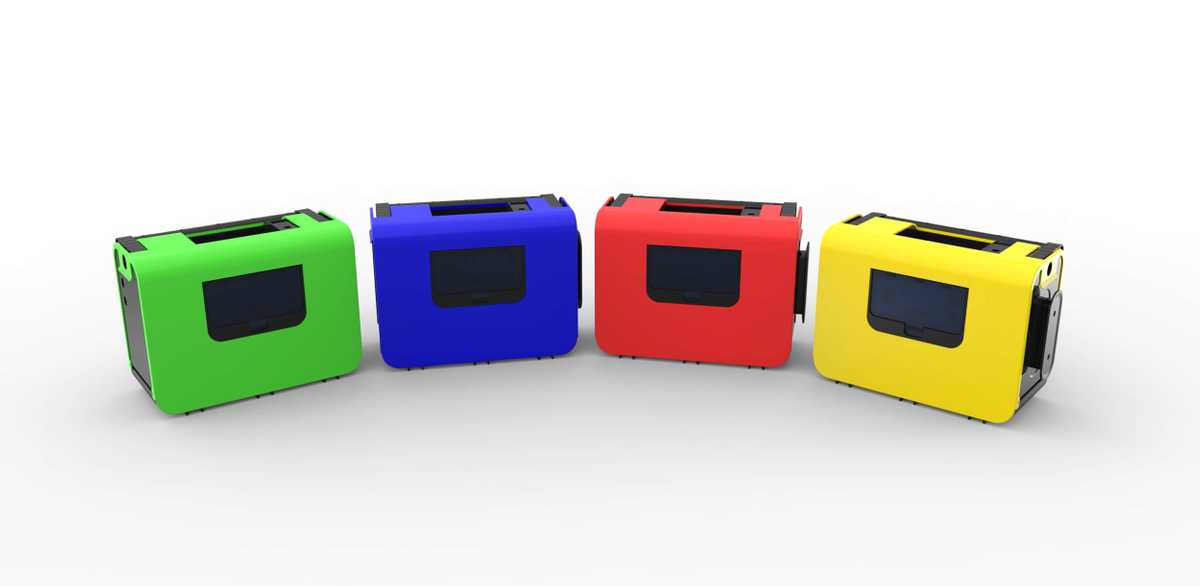

Proposal renders of various colour choices

Above - photos of first sample from production tools